Unbody frame repair is a critical process ensuring auto collision centers deliver high-quality work. It involves meticulous reconstruction of vehicles' structural frameworks, addressing both visible damage and underlying components. This complex procedure requires specialized equipment and skilled technicians for accurate realignment and replacement of parts like chassis rails, cross members, and body panels. Proper unibody frame repair minimizes future repairs, maximizes resale value, and is essential in reputable bodywork facilities. Best practices, mandated by OEMs, prioritize safety and structural integrity through precise quality control, systematic repair procedures, and use of specialized tools and CAD software. Detailed attention to preparation, cleaning, debris removal, priming, measuring, marking, and cutting is crucial to avoid misalignment and weak spots, ensuring both safety and aesthetic quality.

In the automotive industry, Original Equipment Manufacturer (OEM) guidelines are paramount for ensuring structural integrity during unibody frame repairs. This article delves into the intricacies of unibody frame repair, highlighting its basic concepts and significance. We explore OEM best practices, offering a strategic roadmap for achieving precise and reliable repairs. Additionally, we identify common mistakes to avoid, empowering professionals with the knowledge to deliver superior workmanship. Mastering these techniques is crucial for maintaining vehicle safety and performance.

- Understanding Unibody Frame Repair: The Basics and Importance

- OEM Best Practices for Unibody Frame Repair Techniques

- Common Mistakes to Avoid During Unibody Frame Repairs

Understanding Unibody Frame Repair: The Basics and Importance

Unbody frame repair is a critical process that forms the backbone of any quality auto collision center’s operations. At its core, unibody frame repair involves the meticulous reconstruction of a vehicle’s structural framework, ensuring it regains its original integrity and safety standards after an accident. This isn’t merely about fixing visible dents; it encompasses realigning and replacing damaged components to prevent long-term structural issues that could compromise passenger safety.

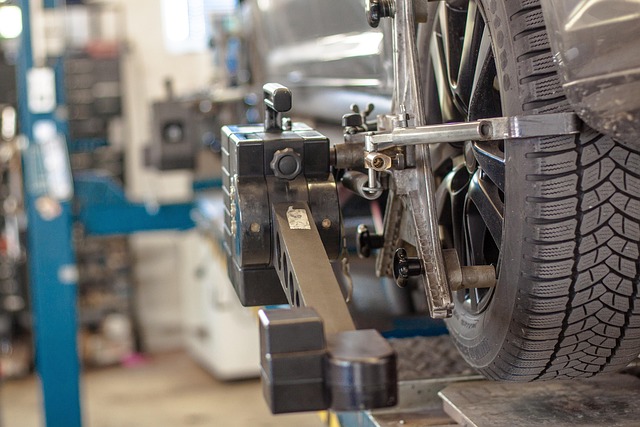

The importance of proficient unibody frame repair cannot be overstated. It’s a complex process requiring specialized equipment and skilled technicians to accurately measure, adjust, and replace parts like chassis rails, cross members, and body panels. Getting it right is paramount to ensure the car retains its original handling, performance, and most importantly, safety ratings. Proper frame repair is also key in minimizing long-term repairs and maximizing resale value for a vehicle, making it an indispensable service in any reputable car bodywork facility.

OEM Best Practices for Unibody Frame Repair Techniques

When it comes to unibody frame repair, Original Equipment Manufacturer (OEM) best practices are crucial for maintaining vehicle safety and structural integrity. These guidelines emphasize precision and quality control throughout the repair process. Technicians should utilize specialized tools and equipment designed for unibody repairs, ensuring minimal displacement of metal components. The use of computer-aided design (CAD) software is often recommended to accurately measure and adjust the frame, returning it to its original specifications. Proper training and certification are essential for repair technicians to stay up-to-date with industry standards and the latest technology in unibody frame repairs.

OEMs also advocate for a systematic approach to unbody frame repairs, starting with a thorough inspection to identify damage and plan the repair sequence. This involves assessing each component, including auto glass repair, tire services, and collision center procedures, to ensure they are replaced or refurbished according to OEM standards. A well-coordinated repair process, adhering to these guidelines, can significantly reduce the risk of future structural issues and enhance vehicle performance after a collision.

Common Mistakes to Avoid During Unibody Frame Repairs

During unbody frame repairs, several common mistakes can compromise the structural integrity and overall quality of the vehicle. One of the most frequent errors is using unsuitable replacement parts, which may differ in dimensions or material properties from the original components. This inconsistency can lead to poor alignment, reduced strength, and unsightly gaps, affecting both the safety and aesthetics of the repaired car.

Another mistake to avoid is inadequate preparation of the damaged area. Insufficient surface cleaning, removal of debris, and priming can result in subpar adhesion of repair materials. Moreover, skipping crucial steps like measuring, marking, and cutting accurately may cause misalignment and weak spots in the frame, making the vehicle more susceptible to future damage. Utilizing collision repair services from a reputable vehicle body shop ensures these mistakes are sidestepped, guaranteeing precise unbody frame repairs that maintain both safety standards and car bodywork excellence.

In conclusion, mastering unibody frame repair techniques is paramount for ensuring vehicle structural integrity and safety. By adhering to OEM guidelines and best practices discussed in this article, repair professionals can effectively navigate the intricacies of unibody repairs, minimizing common mistakes and maximizing the quality of their work. Understanding the basics and staying informed about industry standards are key steps towards becoming an expert in this specialized field, ultimately contributing to the longevity and performance of vehicles across the globe.